Photovoltaik-Klammer-Klassifizierung und Optimierung design

Release-Zeit:

Apr 15,2024

Anaphora

At present, the common forms of photovoltaic brackets in China are: fixed brackets, fixed adjustable Angle brackets, tracking brackets, and flexible brackets and floating brackets applied to special scenarios.

Although the market share has increased year by year as the technology development of fixed and adjustable tracking brackets has gradually matured, the fixed bracket market share is still as high as 70% to 80%, and it is still the mainstream in photovoltaic brackets. This paper focuses on the classification of fixed bracket, fixed adjustable Angle bracket and tracking bracket, and makes a preliminary exchange and share on the optimization design of fixed bracket.

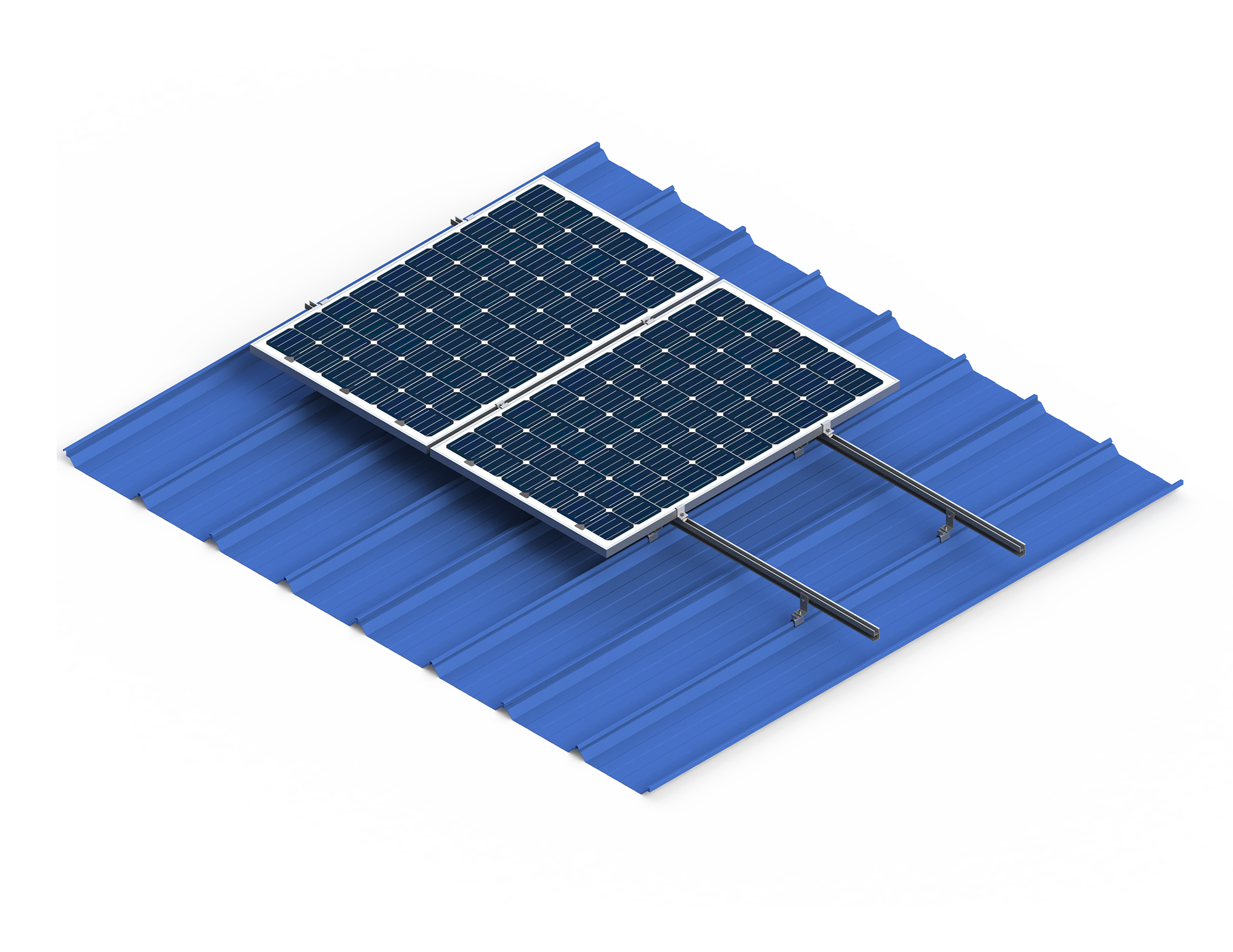

01, fixed bracket

The above figures are respectively: double column bracket structure profile and single pile bracket structure profile

At present, the most mature technology, the lowest cost and the most widely used way is fixed installation. The common structural forms of fixed structure include the two-column support system scheme and the single-pile support system scheme.

All adopt a fixed Angle, facing due south, generally choose the maximum annual component surface irradiation of the fixed bracket Angle, the advantage is that the accuracy of the foundation is relatively low, the structure is simple and the maintenance is less, but the fixed bracket has the lowest power generation among all bracket types.

02, fixed adjustable bracket

The fixed adjustable bracket is basically a single column form at present, which is classified by adjustment, and the common types are as follows.

Type 1: Card slot fixed

Card slot fixed bracket is provided with a card slot, adjust the movable arm, adjust the movable arm and the beam connection, the short horizontal component is provided with a card slot and the column connection. The fixed structure of the card slot is relatively simple, but the adjustment needs to be adjusted by many people during mediation, the synchronization is poor, the adjustment efficiency is low, and the connection between the support rod and the column is easy to rust, and the subsequent maintenance cost is high.

Type 2: curved arc beam type

The curved arc beam structure is similar to the fixed bracket. The curved arc beam is used to replace the diagonal brace of the fixed bracket and is positioned on the curved arc beam. The curved arc beam also needs to be adjusted by many people, but the rotation of the support is less labor, the adjustment efficiency is higher, the structure is reliable, and the subsequent maintenance cost is low.

Type 3: Jack type

Jack type is a fixed and adjustable structure composed of jack as a driving and stopping device. The adjustable bracket has a manual adjustment and electric adjustment interface, the adjustment tool is relatively light, can be reused, cycle operation, can effectively reduce the burden of staff, improve the adjustment efficiency. However, the adjustable silk teeth are exposed, vulnerable to wind and sand intrusion, and the subsequent maintenance cost is higher.

03, tracking bracket

The height Angle of the sun in the same location is constantly changing within a day, so the tilt Angle of the photovoltaic array to receive the maximum amount of solar radiation at different times is also constantly changing. The function of the tracking system is to use algorithms to determine the real-time position of the sun, and monitor the motor Angle through the motor encoder, so that the sun is always aligned with the panel to obtain the maximum incident solar radiation energy. Under the premise of ensuring the safe operation of the support, the optimal power generation Angle of the component is calculated in real time based on the optimal power generation performance of the component, and the common types are as follows.

Type 1: Flat single-axis tracking bracket

The axis of the flat single-axis tracking bracket is north-south, and the assembly rotates from east to west to track the solar azimuth. It has the advantages of no higher requirement for foundation accuracy than fixed support, low civil construction cost, saving pile foundation, multi-point support, strong wind resistance, low structural cost, low KWH cost, high yield and cost-effective.

Type 2: Inclined single-axis tracking bracket

The axis of the inclined single-axis tracking bracket is north-south, and the north is high and the south is low, which is more conducive to the collection of light radiation than the flat single-axis. It has the advantages of requiring no higher accuracy than the fixed support, low civil construction cost, and is more suitable for high latitude areas, etc. The disadvantage is the deviation of wind resistance, large footprint, high price, and low yield and cost performance in the application of large ground stations.

Type 3: Two-axis tracking bracket

The two-axis tracking system can track the sun's azimuth and altitude Angle and accurately track the sun in real time. The advantage is that the dual-axis increase power generation is the highest among all bracket types, which is 25% ~ 35% higher than that of fixed bracket; The disadvantages are high price, large initial investment, large footprint (about 2 times of the fixed bracket), high maintenance costs in the later period, and low cost performance in large ground station applications.

04, fixed bracket design optimization

The amount of steel used in the bracket has a great impact on the project cost, so it is necessary to optimize the design in order to reduce the cost. The fixed bracket is studied, the only variable is controlled, and the total steel used is compared and analyzed after the design scheme is obtained. The three core variables include the comparison of equidistant bracket structure with different spacing, the comparison of unequal distance bracket structure and the comparison of large and small bracket structure.

The comparison of the size of the support structure, that is, the comparison of the amount of steel used in the design scheme with different span number and number of components under the same design input conditions, is converted to the same number of components.

Unequal spacing small support assembly support layout

The comparison of the different spacing of the equidistant support structure, that is, the comparison of the amount of steel used in the design scheme of different support spacing under the same design input conditions.

Design optimization conclusion:

1, with the increase of the distance between the north and south piles of the support, the purlin section increases, and the amount of steel used in the support system increases. Therefore, from the point of view of the steel structure engineering quantity, try to choose a small cross-section of purlins, that is, small span of support spacing.

2, if the conditions allow, choose the span of unequal spacing, can reduce the bending moment of the purlin, thereby reducing the amount of steel purlin.

3, the amount of steel used for the size of the bracket because the purlin section has not changed, so the amount of steel used is closer.

05. Summary

Various types of bracket forms have been used in practical projects led by design companies, effectively improving the power generation of photovoltaic modules. And through the design and optimization of the support system, the amount of steel used in the support is effectively reduced, and the purpose of cost reduction and efficiency increase is achieved.

Photovoltaic power generation has become the main force in the new energy, with the rapid development of photovoltaic, that is, safe and reliable and can reduce costs and increase efficiency of the bracket form is also constantly updated and iterated. While actively learning and exploring new types of support, for specific projects, scientific comparison and analysis should be carried out according to the actual situation of the project, and on the basis of ensuring the economy and safety of the project, the most suitable type of support for the project should be selected and optimized.

Verwandte Nachrichten